TRENCHING VS. BLASTING IN FILER, ID

Serving the Twin Falls, ID, Area

Whether you're building a new house or a new office building, you need to deal with the rock you encounter during construction. As you deal with this process, you can choose from two main options: blasting or trenching.

Since the rock excavation will happen on your property, you want to make an informed decision before proceeding. Below, we'll tell you why trenching is usually your best option if you live or work near Twin Falls, ID.

Since the rock excavation will happen on your property, you want to make an informed decision before proceeding. Below, we'll tell you why trenching is usually your best option if you live or work near Twin Falls, ID.

Learn About Trenching

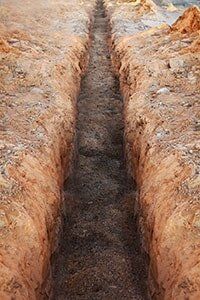

Trenching is a safe, stable way to deal with rock on your construction site. The process begins as trenching professionals use rock trenching equipment to slice through layers of soil and pavement. This movement creates a symmetrical, precise trench with vertical walls that doesn't disturb any surrounding structures.

The trenching process doesn't let helpful material go to waste. You can often use the material from the trench as back fill material. The open top of the trench is symmetrical and uniform, which makes it easy to fill.

Although trenching might require more excavation than other methods, it pays off in the long run-trenching costs less than other methods and doesn't damage nearby structures.

The trenching process doesn't let helpful material go to waste. You can often use the material from the trench as back fill material. The open top of the trench is symmetrical and uniform, which makes it easy to fill.

Although trenching might require more excavation than other methods, it pays off in the long run-trenching costs less than other methods and doesn't damage nearby structures.

Learn About Blasting

Initially, blasting seems like a quick, easy way to deal with rock. However, as a machine hammers or blasts through solid rock or pavement, it sends shock waves through the surrounding material. The impact can damage other structures, and your company will likely have to pay for the damage caused or for any liability incurred.

Blasting and hammering produces a symmetrical walls that are harder to fill, and the material removed from the area can't usually be used to back fill the trench. Unlike trenching, the blasting process doesn't help with compaction. As surrounding structures settle after being disrupted by hammering, the restructured trench might start to sink.

Blasting and hammering produces a symmetrical walls that are harder to fill, and the material removed from the area can't usually be used to back fill the trench. Unlike trenching, the blasting process doesn't help with compaction. As surrounding structures settle after being disrupted by hammering, the restructured trench might start to sink.

Choose Lancaster Trenching Inc. for Your Trenching Needs

As you decide whether or not to choose trenching over blasting or hammering, get in touch with our professionals. We're happy to look at your

site and explain how trenching can save you money and time-not to mention lessen your liability for structures near your construction area.

Our company can help you deal with utilities, pipelines, sewer lines, wind farms, subdivisions, water lines, utilities, and any other construction project that requires trenching.

When you work with us, we're sure you'll be satisfied with our process and results. To learn more,call 208-326-5929 or fill out the contact form at the bottom of this page.

Our company can help you deal with utilities, pipelines, sewer lines, wind farms, subdivisions, water lines, utilities, and any other construction project that requires trenching.

When you work with us, we're sure you'll be satisfied with our process and results. To learn more,call 208-326-5929 or fill out the contact form at the bottom of this page.

Trenching

Trenches have regular dimensions that will leave surrounding structures undisturbed. Trench walls are vertical, decreasing excavation. The trench has a flat bottom which is straight and at a measured grade.

Backfilling and finishing are minimized. Soil from the trencher is often usable as backfill material saving your project money. Uniform trench walls aid compaction. The minimal opening at the top of the trench conserves patching materials.

Blasting

Uneven, sloped trench walls are produced. This requires greater excavation effort. Surrounding rock is often disturbed from blasting and excavating.

New backfill material is usually needed. The irregular trench walls resist compaction. Surface patching costs more due to wider opening and irregular trench edges. As surrounding structure settles, surface sinking may occur.

Contact the trenching and excavation experts today in Filer, Idaho

by calling 208-326-5929

to receive more information.